From left to right, John Wagner, Secretary Granholm, Jeff Lyash, Chris Womack, have a discussion during the opening plenary of the ANS Annual Conference.

The 2024 American Nuclear Society Annual Conference opened with a bang yesterday as 1,200 attendees gathered in Las Vegas to network, collaborate, and socialize. Honors and awards were presented to several recipients, and ANS welcomed twelve new Fellows.

The plenary opened with an address from ANS Executive Director/Chief Executive Officer Craig Piercy that brought this year’s theme to the fore straight away: The time is now to deploy new nuclear projects—and not acting at this moment is simply not an option.

December 15, 2023, 4:56PMNuclear NewsDonna Kemp Spangler and Joel Hiller BWXT’s microreactor components would be designed to be transported directly from the factory to the deployment site. (Image: BWXT)

“The tools of the academic designer are a piece of paper and a pencil with an eraser. If a mistake is made, it can always be erased and changed. If the practical-reactor designer errs, he wears the mistake around his neck; it cannot be erased. Everyone sees it.”

Many in the nuclear community are familiar with this sentiment from Admiral Rickover. A generation of stagnation in the industry has underscored the truth of his words. But as economies around the world put a price on carbon emissions, there’s a renewed sense of urgency to deploy clean energy technologies. This shifts the global balance of economic competitiveness, and it’s clear that the best path forward for nuclear requires combining the agility of private innovators with the technology and capabilities of national laboratories.

Joint efforts of Argonne and private industry further nuclear reactor developments

Partnerships between the nuclear industry and national laboratories are making overall codes more robust and capable. (Photo: Argonne)

The development of modern nuclear reactor technologies relies heavily on complex software codes and computer simulations to support the design, construction, and testing of physical hardware systems. These tools allow for rigorous testing of theory and thorough verification of design under various use or transient power scenarios.

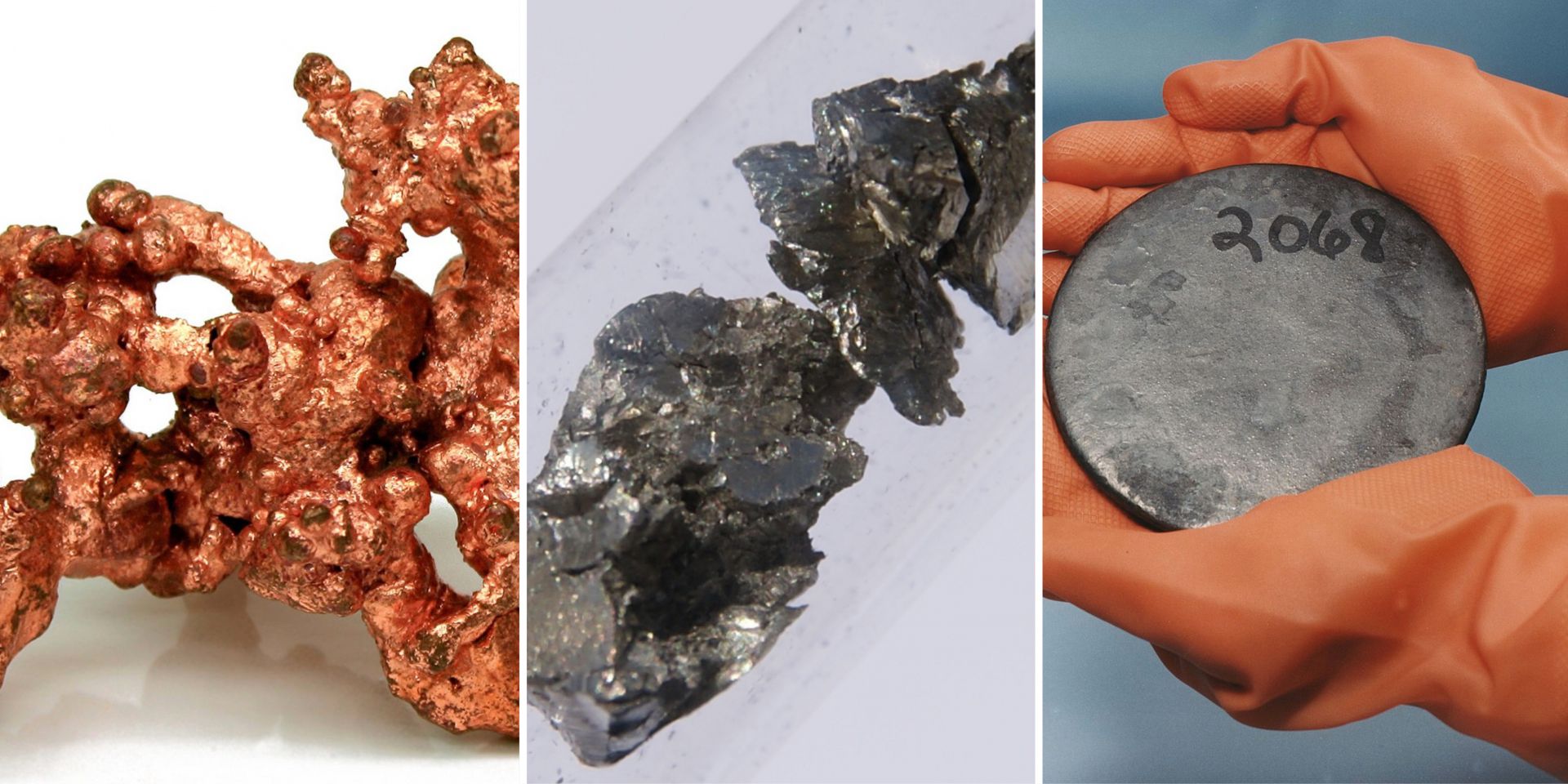

Three of the USGS's critical minerals: (Left to right) A piece of native copper recovered by dissolution of the host rock (Photo: Jonathan Zander); A sample of praseodymium in a vial of argon (Photo: Jurii/Wikimedia Commons); A billet of high-enriched uranium that was recovered from scrap processed at the DOE’s Y-12 National Security Complex in Oak Ridge, Tenn (Photo: DOE).

Last year, the U.S. Geological Survey (USGS) released its 2022 list of 50 minerals that are essential to the function of our society, especially the economy and national security. Whether it’s indium for LCD screens and aircraft wind shielding, cobalt for iPhones, uranium for nuclear reactors and munitions, rare earth elements for wind turbine magnets, lithium for rechargeable batteries, or tantalum for electronic components, if we do not have an ample supply, bad things will happen.

PCAT is prepared for transport from INL to Pennsylvania for testing. (Photo: INL)

As global concerns about climate change and energy sustainability intensify, the need for cleaner and more efficient energy sources is more critical than ever. Nuclear power consistently emerges as an important part of the solution, driving the development of innovative technologies. While numerous fission technologies were built and proven in the early days of nuclear energy, times and regulations have changed. Between the 1950s and mid-1970s, Idaho National Laboratory built 52 reactors—then paused for five decades. Can this nation return to the frontier once again, embarking on new fission technologies? With a mature regulatory environment and increasing public support, how quickly can a new non–light water system be deployed in modern times?

The National Reactor Testing Station (Photo: DOE)

Gas-cooled reactors have roots that reach way back to the development of early experimental reactors in the United States and Europe. In the United States, early experimental reactors at Oak Ridge and Brookhaven National Laboratories were air-cooled, as were early production reactors known as the “Windscale Piles” in the United Kingdom. Dragon, also located in the United Kingdon and operational from 1965 to 1976, used helium as the coolant and graphite as the moderator.

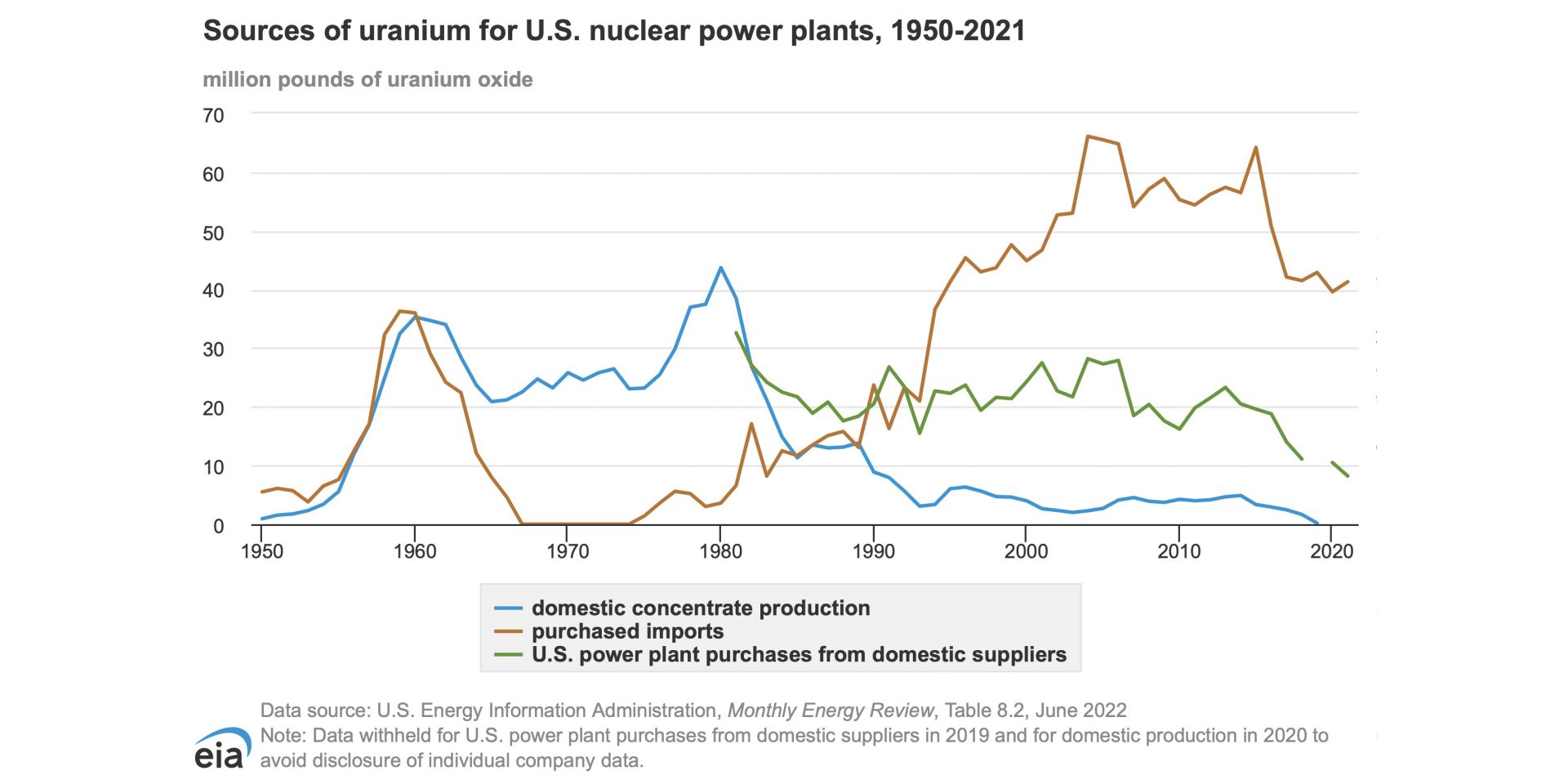

This chart from the EIA shows sources of uranium for U.S. nuclear power plants, 1950-2021. In 2020, according to the chart, 39.60 million pounds of uranium oxide was imported for the domestic nuclear power plant fleet. (Credit: Energy Information Agency)

The naturalist John Muir is widely quoted as saying, “When we try to pick out anything by itself, we find it hitched to everything else in the Universe.” While he was speaking of ecology, he might as well have been talking about nuclear fuel.

At the moment, by most accounts, nuclear fuel is in crisis for a lot of reasons that weave together like a Gordian knot. Today, despite decades of assertions from nuclear energy supporters that the supply of uranium is secure and will last much longer than fossil fuels, the West is in a blind alley. We find ourselves in conflict with Russia with ominous implications for uranium, for which Russia holds about a 14 percent share of the global market, and for two processes that prepare uranium for fabrication into reactor fuel: conversion (for which Russia has a 27 percent share) and enrichment (a 39 percent share).

Using GeoMelt ICV technology to treat and immobilize problematic low-level wastes at INL and WCS.

A sample of GeoMelt glass. (Photos: Veolia)

When it comes to managing nuclear waste, technology is transforming the way some of the most problematic waste is handled. The idea to transform nuclear waste into glass was developed back in the 1970s as a way to lock away the waste’s radioactive elements and prevent them from escaping. For more than 40 years, vitrification has been used for the immobilization of high-level radioactive waste in many countries around the world, including the United States.

February 17, 2023, 3:03PMRadwaste SolutionsPeter Swift, Michael Apted, Lake Barrett, John Kessler, and Steven Nesbit An electric continuous miner machine cuts out a waste-emplacement panel at the Waste Isolation Pilot Plant salt repository in New Mexico. (Photo: DOE)

Used nuclear fuel and high-level radioactive wastes are by-products of nuclear energy production and other applications of nuclear technology, and the consensus approach to disposing of those wastes safely is to encapsulate them and emplace them in stable geologic formations (geologic repositories) where they will be isolated from people and the environment for very long periods of time. The federal government has established environmental standards for waste isolation that any proposed geologic repository must meet.

In July 2021, the American Nuclear Society established a special committee to consider possibilities for revised generic environmental standards for disposal of spent nuclear fuel and high-level radioactive waste in the United States. The committee developed a number of recommendations, which are contained in a draft report that was to be issued in February for review and comment by stakeholders. The draft report can be found on the ANS website, at ans.org/policy/repositorystandard/.

The committee’s draft recommendations are based on two underlying assumptions. First, that the relevant legislative framework for regulation defined in the Nuclear Waste Policy Act (NWPA) remains unchanged. Specifically, it is assumed that the Environmental Protection Agency will be charged with promulgating environmental standards for disposal and that the Nuclear Regulatory Commission will be charged with reviewing applications for disposal facilities using licensing requirements and criteria consistent with the EPA standards. Second, that existing generic disposal standards will be updated or replaced.

Comments due April 14 for draft report aimed at revisiting EPA regulations

LA GRANGE PARK, Illinois – Today, the American Nuclear Society (ANS) released draft recommendations on updating public health and safety standards for the permanent disposal of commercial used nuclear fuel and high-level radioactive waste at future geological repository projects in the United States. The draft report provides a recommended framework for revisiting U.S. Environmental Protection Agency (EPA) geologic repository standards.

Front face of the B Reactor at the Hanford Site. (Photo: DOE)

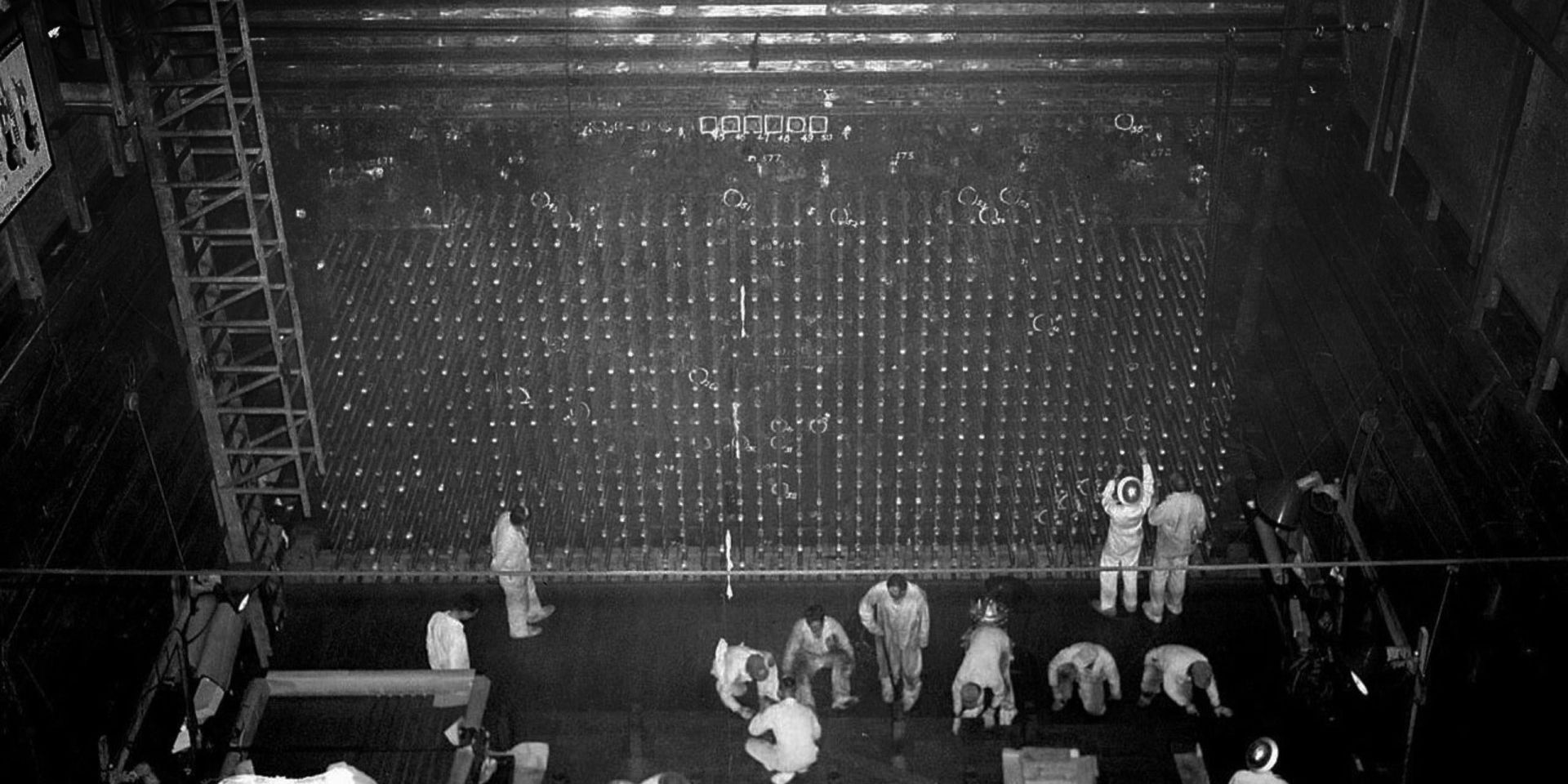

In remote southeastern Washington you will find the sprawling Hanford Site, which was constructed to produce plutonium for the Manhattan Project. Within this complex is the first plutonium production reactor, the Hanford B Reactor. The DuPont Corporation was responsible for construction and operation of the B Reactor. Due to the urgency of the Manhattan Project, construction was completed in just over a year, and The B Reactor went critical on September 26, 1944. After the needs of the Manhattan Project were satisfied, the reactor was briefly shut down and then restarted to produce plutonium for roughly another 20 years, supporting Cold War efforts. In addition to plutonium production, the B Reactor also pioneered the process to produce tritium for the first-ever thermonuclear test.

2x1.jpg)